Contributor

- Topics: Archive, Sustainable Gardening

[sidebar] Beta Hatch

[sidebar] Beta Hatch

www.betahatch.com[/sidebar]

Since the summer of 2015, Beta Hatch has grown from one woman’s solitary experiment in her backyard “Bug Barn” in Ballard, into an innovative Pacific Northwest startup that today employs a team of eight. Their mission: to “think outside the field” and create a whole new sector of agriculture. Read on to discover why this is good news for gardeners.

A conversation between editor Lorene Edwards Forkner and Virginia Emery, PhD

LEF: On your business card you call yourself an “Insect Entrepreneur,” please explain.

VE: I have a PhD in entomology from UC Berkeley and I’m passionate about bugs. I also think a lot about agriculture and how we’re going to feed our growing human population. At Beta Hatch we grow insect protein for animal feed using our expertise in entomology to raise the most efficient and nutritious insects. And a sterile by-product of that process is a balanced fertilizer and soil amendment.

LEF: How? Or I guess first I should say, why?

VE: When asked why—and we get that a lot—we tell people we think farming insects is a game-changer. Most people consider bugs to be pests; we want to shift that attitude from antagonistic to beneficial. Insects are a nutritious and space-efficient crop, and they are also some of nature’s most efficient bioreactors.

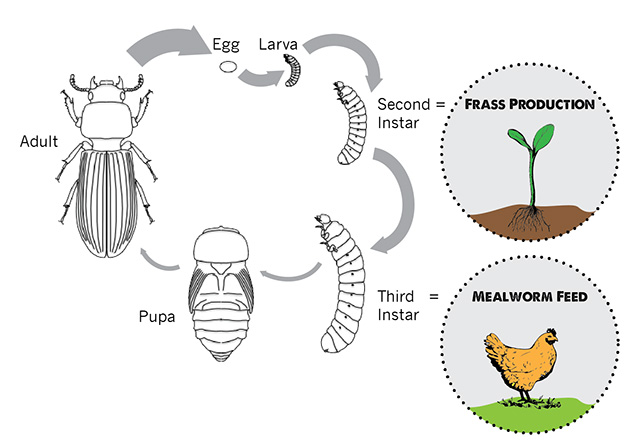

As to how, our process is a tidy closed-loop system. Our insects are grown on an all-organic diet, sourced from local farmers and suppliers. Our farm is an indoor, climate-controlled space that is customized to keep the insects healthy and happy. Currently we’re raising Tenebrio molitor, also known as a mealworm or darkling beetle.

In time, we’ll harvest mealworm larvae right before they pupate when they’re at maximum protein and fat levels. Frass—or insect manure—is harvested as the insects grow. And we can do all this without any additional direct watering—the insects get all the moisture they need from their feed. Every pound of feed yields one pound of mealworms and two pounds of frass. Our goal is to maintain efficient production and a zero-waste system.

Right now we’re concentrating on building up our number of animals so we can ramp up production. Already we’ve got 15 times as many animals as we did last year. So now we’re focusing on establishing a stable production system that produces a consistent soil amendment. Our frass-based fertilizer is rich in beneficial microbes and is nitrate-free. It has a sandy texture and smells earthy; this is a no- or low-smell product. Certainly compared to fish fertilizer! You can use Beta Hatch fertilizer indoors as well as out.

LEF: But this is about more than bugs, right?

VE: Sustainability is the unifying thrust behind Beta Hatch. As a science-driven company, we’re constantly innovating our methods and exploring new ways to use our products. Some of our current projects include transforming spent brewery grain into insect feed and exploring the ways that insect exoskeletons could be used for bioplastics, pharmaceuticals, and more. We’re also collaborating with scientists at Stanford to investigate the viability of using mealworms to biodegrade Styrofoam.

LEF: What’s next?

VE: We’re expecting our first large-scale harvest of mealworms this month (January 2017); the eggs have hatched and the animals are growing. It takes about 10 to 12 weeks from egg to harvest.

Currently, we’re in the process of obtaining organic certification. And by early spring we expect to have permits in place that will allow us to distribute our products in all 50 states. In the meantime, you can order Beta Hatch fertilizer online through Amazon.

You can find more information about ordering our products on our website at www.betahatch.com.

You can find more information about ordering our products on our website at www.betahatch.com.

Responses